Lychee Slicer seems to be best DLP slicer out there right now hands down. And it's the only one apart from the Photon Workshop which not only supports the pwmx format, but also has Mono X profile built in. Please consider giving me a thumbs up if you like my video. That would mean a lot for me.Recently many of my friends bought a LCD (MSLA) Resin printer.Some o.

- Anycubic Photon Slicer Software Mac Pro

- Anycubic Photon Slicer Software Macromedia

- Anycubic Photon Slicer Software Machine

Looking to buy the Anycubic Photon S? We recently got our hands on the printer and took it for a test drive. Read our Anycubic Photon S review to find out the specs, performance, quality of prints, and price of the 3D printer.

SLA 3D printers have their advantages and disadvantages. We previously tested the Elegoo Mars (read the review) and were happy to get the Anycubic Photon S.

Our Anycubic Photon S review follows.

BUY ATAliExpress |Amazon | GearBest

Anycubic Photon S 3D printer Highlights

- Print space: 115 x 65 x 165 mm – up to 0.01 mm layer height

- Special features: two Z-axes, improved UV module and “plastic housing”

- Accessories: 1 x 500 ml resin, 2 x extra FEP foils and 15 x paper filters

The Elegoo Mars was the first SLA 3D printer we tested. As a fan of Miniature Wargaming , I was particularly enthusiastic about the higher level of detail compared to FDM printers.

I’ve already done several prints with Mars. I’ve tried a lot with different exposure times and automatic and manually set support structures – with variable success. That’s probably how everyone feels at the beginning. 🙂

I’ve now had a chance to look at the Photon S from start to finish. Here is my review.

Anycubic Photon S Review

The Photon S is an upgrade of the Anycubic Photon. With the Photon S, the Z-axis has been improved (double guidance) and the lighting has a little more power (50W instead of 40W).

The printer is also now largely made of plastic, which makes it about 700g lighter.

Scope of Delivery

We ordered the Anycubic printer through Amazon and it arrived in our warehouse in a few days.

After opening the box, you’ll see the printer and its accessories wrapped in foam. The foam helps to prevent collisions during shipment. The best thing is that Amazon has a return policy, just in case your printer arrives damaged.

The Anycubic Photon S case is made of plastic. As a result, the cladding just doesn’t feel stable. Therefore, you should be careful when removing the printer from the box.

I like the flap much better than the cover on the Elegoo Mars. The flap looks better during the printing process because you can see more. However, it has to be lifted completely from the printer every time.

Equipment

The box contains the instructions manual written in English. The instructions are thorough and contain illustrated steps on the structure, the setup and the functions of the slicing software.

There is also a bottle of green resin in the packaging for your first test prints.

Other items included in the package include a mouth mask and some gloves, ten disposable filters for refilling the resin, a plastic scraper, hexagon screwdrivers of various sizes or Allen keys, a USB stick (4 GB), FEP foils for the resin tank and a power cord.

However, I didn’t see any small pliers, which you will later need when removing the support structures of the prints.

Anycubic Photon S Setup

There is actually no real set-up process. If you know what you are doing or follow the instructions in the manual, you will be ready to use the printer in five minutes.

You can first remove the resin tub (leveling is also possible with a tub and without paper). Loosen the two adjusting screws and carefully pull the tray forward out of the printer.

Follow the steps below to correctly level the printer.

Loosen the platform by loosening the large set screw and take it out of the printer. Use one of the enclosed Allen keys to loosen the platform so that it can be moved relatively freely and then attach it to the lift again.

On the printer’s menu, navigate to the manual operation of the Z-axis via Tools and “Move Z”. Press the home button to make the platform move to the starting position.

Place a sheet of paper between the screen and the platform and lower the platform in 0.1mm steps until the sheet can only be pulled out with resistance. Do this in small steps so as not to damage the screen.

When you have reached this position, gently press the platform into place to test that all corners are touching the ground and that it is fully balanced. Finally, tighten the platform again.

The whole process is also explained quite precisely in the instructions. The process is important, and once done correctly, you don’t have to level for the next few prints.

Before the first pressure, fill the resin in the tub. How much resin you will need will depend on the pressure. The ChiTu slicer software will indicate the required amount of resin. However, to be on the safe side, simply pour a little more into the tub. You can also fill it back into the bottle with the enclosed filters.

Operating the Anycubic Photon S

The Anycubic Photon S is operated entirely via the touchscreen on the front. The on/off switch is on the right and turns on the printer and the display. Most of what you see is self-explanatory.

After a short loading time you will see the start screen, where you can choose between print, system and tools.

Under Print is the file view of the USB stick (if you have one plugged in). You can choose between the available print files and you’ll see a preview image.

After choosing a file, you can either delete or print it. You can also go back on the menu.

Under System, you will find the Language, Service and Info. Pressing Language changes the language to Chinese.

Finally, the Tools menu item gives you the option of moving the Z-axis manually, which is important when leveling, among other things.

Detection also lets the lighting test what should be done before the first print, and Z=0 defines the new zero point of the Z axis.

You can also turn off the key tone here. Otherwise, a rather annoying beep will sound each time a key is pressed.

Quality of Print

There is no printing without slicing.

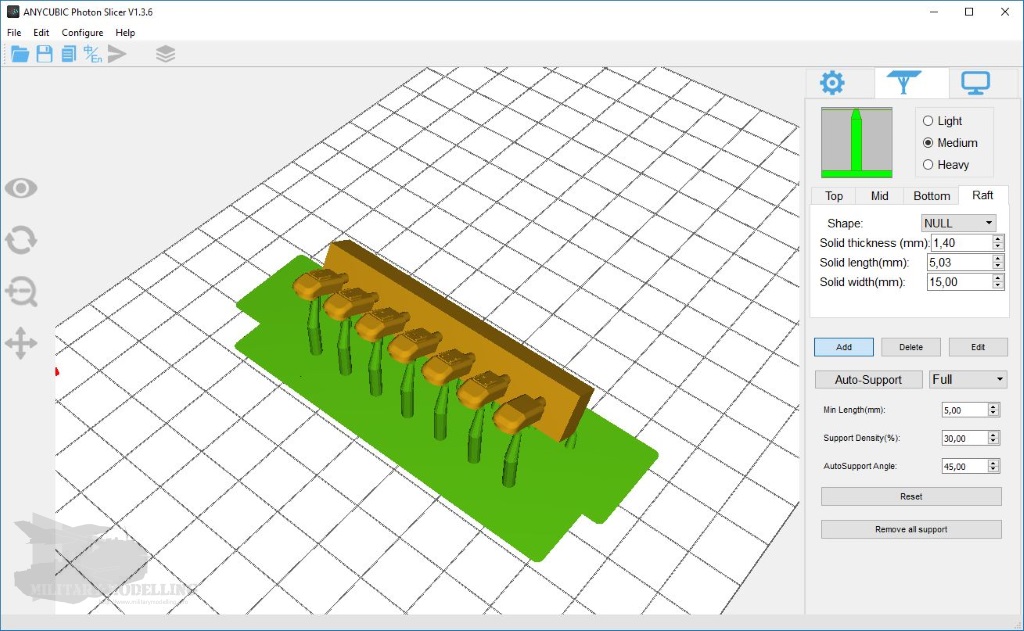

While the actual printing process takes place without your intervention, you need to “slice” the model to be printed beforehand. Slicing is not difficult. The Anycubic printer comes with its own software Photon WorkShop in the USB stick. The software is available there for both Windows and Mac. Simply install it.

After the installation, start the software and import the test file PHOTONS.stl that is on the stick. Go to File -> Open”, like is shown on the screenshot below.

Follow the instructions in the manual.

You don’t have to set a lot for the first print. You don’t even need support structures at the beginning. If you have set everything, click on Slice and save the file on the stick.

Then, put the memory stick in the printer and select Printing on the touchscreen. The file should be displayed here and you can start printing.

With the suggested settings, printing the test file took a little over six hours. This is an example of how long SLA printing can take.

The result is impressive, especially when you consider that the slicing and preparation of the print took less than ten minutes. The Anycubic Photon lettering inside the cube is perfect.

While the surface of the grid structure looks smooth, the individual layers can also be seen on the lettering with the naked eye. Still, compared to most FDM printers, the level of detail is still outstanding.

BUY ANYCUBIC PHOTON S ATAliExpress |Amazon | GearBest

>Photon WorkShop vs. ChiTuBox: Which Slicing Software Should You Use?

Photon WorkShop

You can now make settings on the object in the slicing program. You can view the object from all sides, change the orientation and size or load multiple files and print them at the same time, as long as there is enough space.

There are some parameter values recommended in the instructions; I have adjusted these accordingly.

Depending on your experience, you can later adjust the layer thickness (how high each individual layer is. The standard is 0.05mm), the exposure time (the duration of the exposure of each individual layer. The standard is 8 seconds) and the speed of the Z-axis. This can greatly reduce the printing time.

Short calculation example:

Let’s say tour layer thickness is 0.05 mm. Therefore, a 5cm high model has a thousand layers. If you increase the exposure time by just one second, the pressure increases by over 16 minutes. If you want to reduce the layer thickness and, for example, only print with 0.02 mm, then the print will take 2.5 times as long as with 0.05 mm – logically.

Later, you can also add support structures, which are essential for many models. Again, the best approach is trial and error. Start with the automatic support structures (just a click of the mouse) and manually adds structures where they are missing. It may take a few prints before you get the hang of it.

ChiTuBox

Unlike the Photon WorkShop, which is tailored to Anycubic, ChiTu is used by several 3D printers. The printers include the Elegoo Mars, printers from Phrozen, SparkMaker, Wanhao and the two Anycubic Photon and Photon S.

ChiTuBox looks a little nicer than the Anycubic program. Apart from that, both slicers are extremely similar. The interface is almost identical, the operation is also the same.

There are a few more options here, however. For example, you can have the model displayed transparently and view the sliced file again before saving. With Photon WorkShop, the file is saved directly.

In ChiTuBox, you can also see the time it will take to print before saving. It really doesn’t take much. ChiTuBox is my software of choice for the Photon S.

After printing

After printing, the finished print still needs to be cleaned. This is usually the case with prints made by SLA printers.

If everything worked, the finished print sticks under the platform, which is raised all the way up after completion.

Unscrew the platform and carefully remove the pressure with the plastic spatula. You can also use other tools for this. However, make sure you use a tool made of metal so as not to scratch the plate. Also, wear gloves to avoid coming into contact with the synthetic resin.

Then, place the print in an isopropyl bath for about three minutes. Isopropyl can also be ordered online. In order not to use up everything after two prints, you can also roughly wash the print off with it or clean it with a cloth soaked with isopropyl. However, you may not achieve the same effect.

The alcohol removes any resin residues from the object. Make sure you wear a face mask because the 70-99% alcohol smells really strong.

Then, the print has to harden under UV light. If you don’t have a special lamp, you can simply put the print in the sun, which takes longer but has the same effect.

Quality of prints & Tips

The quality of the prints is absolutely convincing. And it doesn’t even take many attempts; the first print was a good success.

With a layer height of 0.05 mm (the standard setting), the individual layers can no longer be seen so well with the naked eye. The surface of the grid structure of the test print feels completely smooth.

This can be further improved by reducing the layer height, which is accompanied by a sometimes greatly increased printing time. For this, you can reduce the exposure time of the individual layers. The initial setting is 8 seconds. In my experience so far, this can also be reduced a bit.

Above all, a long exposure time for the first levels is important. The first 5-10 layers should have an exposure time of 40-60 seconds. However, it will be more difficult to release the pressure from the platform; if you already damage the print, the exposure time should be reduced.

If the pressure fails, you only notice it after at least an hour, depending on the settings, because you cannot look into the pool. Only when the platform rises far enough out of the tank will you see whether a model is being printed at all.

If the print fails, the printer does not notice it and simply “prints” on. In this case, a hardened resin layer forms on the bottom of the tank, which you have to carefully remove after canceling the print. You can use a plastic spatula to remove the print.

Some experiences I’ve had so far:

- The remaining resin does not have to be filled back into the bottle immediately after printing. However, try to put it back within two days. This should always be done with the enclosed filters, which you can buy from Amazon .

- Make sure to set support structures for the overhanging points of the model. The printer cannot print “in the air”. Every point needs a connection to the printing platform.

- So far I haven’t had to level up again. Do it thoroughly the first time and screw the platform tight. With this done, you should first be able to make many prints one after the other without being disturbed.

- Make sure there is good ventilation. I made some of the first prints in a small, poorly ventilated room, which can cause discomfort in the long term and is certainly not healthy. Avoid skin contact and wash your hands thoroughly after handling the prints.

You can find many free ready-made models on Thingiverse. I’ve made a few dozen prints now and will continue to print and try out too.

>Conclusion: Is the Anycubic Photon S Worth It?

I’ll divide the conclusion in half.

One of the questions many people have is: Why choose an SLA printer instead of an FDM printer?

Secondly: If choosing an SLA printer, why go for the Photon S?

The clear advantage of SLA printing is simply a much higher level of detail. If you want to print miniature models or small spare parts that have to fit down to the millimeter (screws and nuts, for example), then SLA is definitely the better choice.

In addition, there is almost nothing to set up. You can start printing a few minutes after unpacking.

The disadvantage is the usually much smaller pressure chamber. For particularly large prints, where you can do without the smallest details, filament printing is the better choice. In addition, you handle chemicals when printing. You should never work with the resin without gloves and face mask.

Cleaning and post-processing after printing is also more time-consuming with SLA printing. If you don’t want to do this to yourself, the printers are not for you either.

But if you want an SLA printer, I highly recommend the Anycubic Photon S. Its predecessor, the Anycubic Photon delivers similar results at a cheaper price, ad so does theElegoo Mars.

Compared to Mars, I like the cover, which is much more convenient to open and close. I also like the positioning of the USB port on the side. However, these are worth the extra cost.

The real advantage is more of the 50W UV lighting, which enables slightly shorter exposure times. If you print a lot, this will save time in the long run, especially with the maximum level of detail and a layer height of 0.01 mm.

BUY ATAliExpress | Amazon | GearBest

Cookies and IP addresses allow us to deliver and improve our web content and to provide you with a personalized experience.Our website uses cookies and collects your IP address for these purposes.CHITUBOX Free makes it so easy to prepare your models for SLA/DLP/LCD 3D printing.